"OPTIMISING SOLID-LIQUID SEPARATION & REACTION VESSELS IN DAC, CO2 REMOVAL & CARBON CAPTURE PLANTS

WITH REAL-TIME MONITORING OF BED-LEVELS"

Designed for Solid-Liquid Separation Thickeners

Effective for Direct Air Capture (DAC), Carbon Dioxide Removal (CDR) & Carbon Capture Utilisation & Storage (CCUS) Thickeners & Clarifiers.

Optimise Flocculation & Control Underflow Density

THE SMARTDIVER® ADVANTAGE

Improving Solid-Liquid Separation & Carbonate Precipitation Efficiency.

Compatibility with Harsh Chemical Environments such as Hydroxides & Carbonates.

Ability to handle High Solids Concentrations typical in DAC processes.

SMARTDIVER® DATA ACQUISITION EXAMPLES

The Data acquired from a SmartDiver® will help in consistent monitoring and adjustment of operational parameters.

This Data is necessary to achieve and maintain these stable levels, ensuring the overall effectiveness and sustainability of the refining process.

Data Sample 1: Interface & Mud Levels in a Well-Controlled Stable Tank.

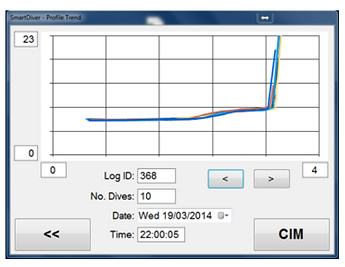

Graph illustrates the relationship between tank depth and solids concentration.

Comprises Data from 10 dives demonstrating measurement consistency as the Overlaid profiles showcase the reliability and precision of the measurement technique.

This Data provides insight into the vertical distribution of solids within the tank.

Data Sample 3: Solids vs Depth Tank Profile - Data from 10 Dives, demonstrating Repeatability.

The graph illustrates a critical period where the interface level surpasses the tank's upper limit, resulting in solids contamination of the overflow.

Concurrent changes in the mud level are depicted, showing instability during the loss of control. Followed by the re-establishment of proper control parameters, with both interface and mud levels returning to their optimal ranges.

This sample data serves as a case study for process upset conditions in thickener operations, highlighting the importance of vigilant monitoring and prompt corrective actions

Data Sample 2: Interface and Mud Level Fluctuations during a Control Loss Event.

Graph illustrates the relationship between Tank Depth and Solids Content.

There is minimal distinction between Interface and Mud layers, indicating a lack of clear Stratification. The Mud layer exhibits low density and minimal compaction. This suggests a relatively Homogeneous Mixture throughout the Tank's vertical profile.

By maintaining distinct mud and interface levels, thickener operations can achieve better separation efficiency, higher overflow clarity, optimized flocculant usage, and more stable and controllable processes overall.